The best Vietnam Oud chip – How it’s made? from HAGA Oud

Oud has always been considered a luxury-grade product. But today in the year of 2022, Oud chips have gradually gained popularity in daily consumption with both luxury and economical criteria, and reasonable prices, especially Vietnam Oud chips.

The best Vietnam Oud chips – How it’s made

How does Hoang Giang Agarwood manufacture one of the best Vietnam Oud chips in the world – HAGA Oud Chip? Have you ever wondered how Vietnam Oud chips are made? Today it will be revealed by the largest Oud manufacturer in Vietnam – Hoang Giang Agarwood with the brand of HAGA Oud.

There are four steps in a closed production process to introduce a perfect thin & clean Vietnam Oud chip product line with the most wonderful scent of nature: from seedlings to handcrafting then distributed around the world.

01. Planting young trees with tender care

Vietnam is entering the beginning of the rains with high humidity and cool days, pouring on seedlings and then nurturing them with gentle care. As a result, this is the most suitable season for planting a new batch of young trees of Aquilaria crassna.

Last week, 20000 seedlings of Aquilaria Crassna were planted at HAGA Oud plantation in an area of 50ha, where we totally control our input raw material for 100% natural Oud production.

HAGA Oud raw material source – Oud used for trading and creating value-added products from Hoang Giang Agarwood manufacturer is supplied from two sources: from Aquilaria Crassna tree plantation of HAGA Oud and from other farmer households that we cooperate with, guide, technology transfer, and off-take.

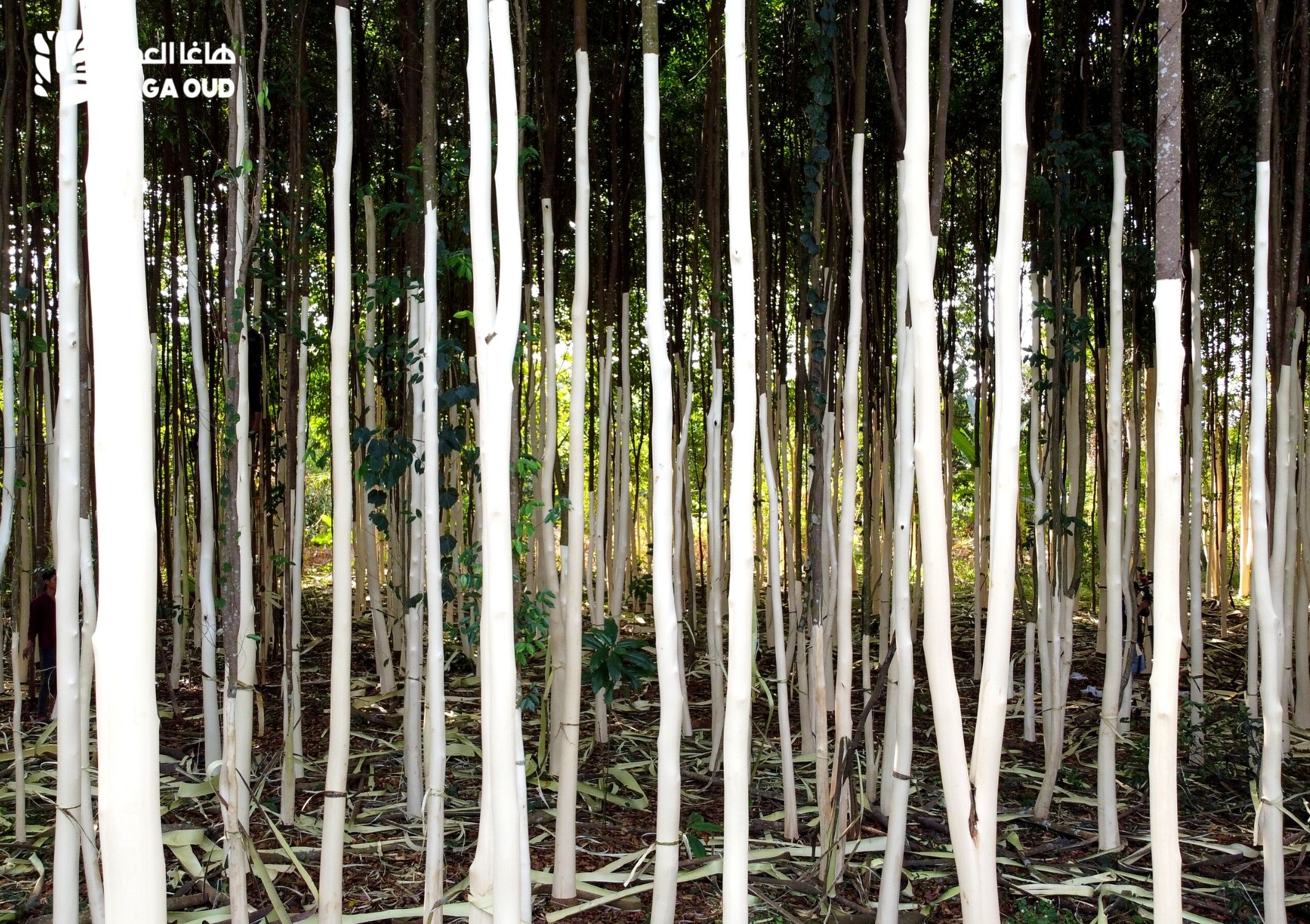

02. Peeling mature trees’ outer layer (10-11years old)

Scientists have concluded that the Oud formation process has 3 methods:

- Mechanical (physical) wounding: this method is very simple and easy to do but the probability of success is low (mainly cutting drum pieces, scrap, nails … to spike into the tree trunk creating mechanical injury to Aquilaria tree to form Oud.

- Impact by some chemical stimuli (chemical): This method is effective for a short duration. However, there is a disadvantage in that in the product, there exist some harmful substances such as CI, SO4, PO3 … that affect the quality of the product and are not favored by consumers.

- The effect of a number of probiotics (biologicals): In essence, this method is to cause diseases in plants with probiotics or certain bacteria that have been identified. Currently, the study of this method has had very positive results, a high success rate, and leaves no residue of harmful substances in the product.

The third method – ‘biologicals’ is also the method that HAGA Oud is using. Before applying bio-compound, it is necessary to peel the outer layer of the trunk. Only mature trees that reach the age of 10-11 years old are eligible.

0.3 Applying bio-compound along the after-peeling trunk

Nowadays, with technical & scientific development, the human can be more active in collecting this precious wood. By using some artificial factors to stimulate the tree to create Oud, such as: implanting insect nests into the tree trunk, using physical elements to inflict wounds, or implanting some kinds of bio-compound. All these methods are used to create wounds so that the tree must secrete its valuable scented resin to heal itself and then provide humans with the wood that they want.

Normally, it takes an Aquilaria Cassna about 10-11 years to reach its mature stage. After that, at Hoang Giang Agarwood manufacturer, we apply bio-compound along the after-peeling trunk to stimulate the tree to produce the resin, which takes 2-3 years to be hard as standard Oud material for harvesting. The whole process may take up to 14 years.

Vietnam Oud chips are cultivated from Aquilaria Crassna trees planted in Hoang Giang Agarwood manufacturer’s plantation, totally free of toxic chemicals or artificial color.

0.4 Skilfully crafted, totally by hand to almost clean white wood

HAGA Oud Chip is peeled off from the injured bark inside Vietnamese Aquilaria Crassna trees, then treated by skilled artisans. After many hours of carefulness, they turn a rough log into a very thin flat chip totally by hand. The majority of the 2 sides are resin, with little white wood left. Thus, when burning these Vietnam Oud chips on charcoal, you will feel a very sweet and warm aroma without the bitter smoke of ordinary wood.

We don’t just cut the resin part and then re-infect them, cause we use the whole mature infected cultivated tree aged 12-13 years, including Oud chip (the thin part), Oud chunk (the trunk core), and the white wood part which is less resin than others.

At HAGA Oud, there is an independently operating QC team to final check all of the finished products, re-ensuring the best quality before worldwide distribution. Pioneering in creating product standards to meet national & international customers’ needs, our specific R&D, and QC teams are continuously innovating the best quality products. Customer surveys by fieldwork are conducted annually at international fairs such as Beautyworld Saudi Arabia, Beautyworld Middle East, and Fragrance Innovation Summit for direct experiences.

Specific R&D and QC teams are Hoang Giang Agarwood manufacturer’s top advantages in building up our reputation as the Vietnam Oud Chip market leader.

How to enjoy Oud chips: advantages of a traditional ritual

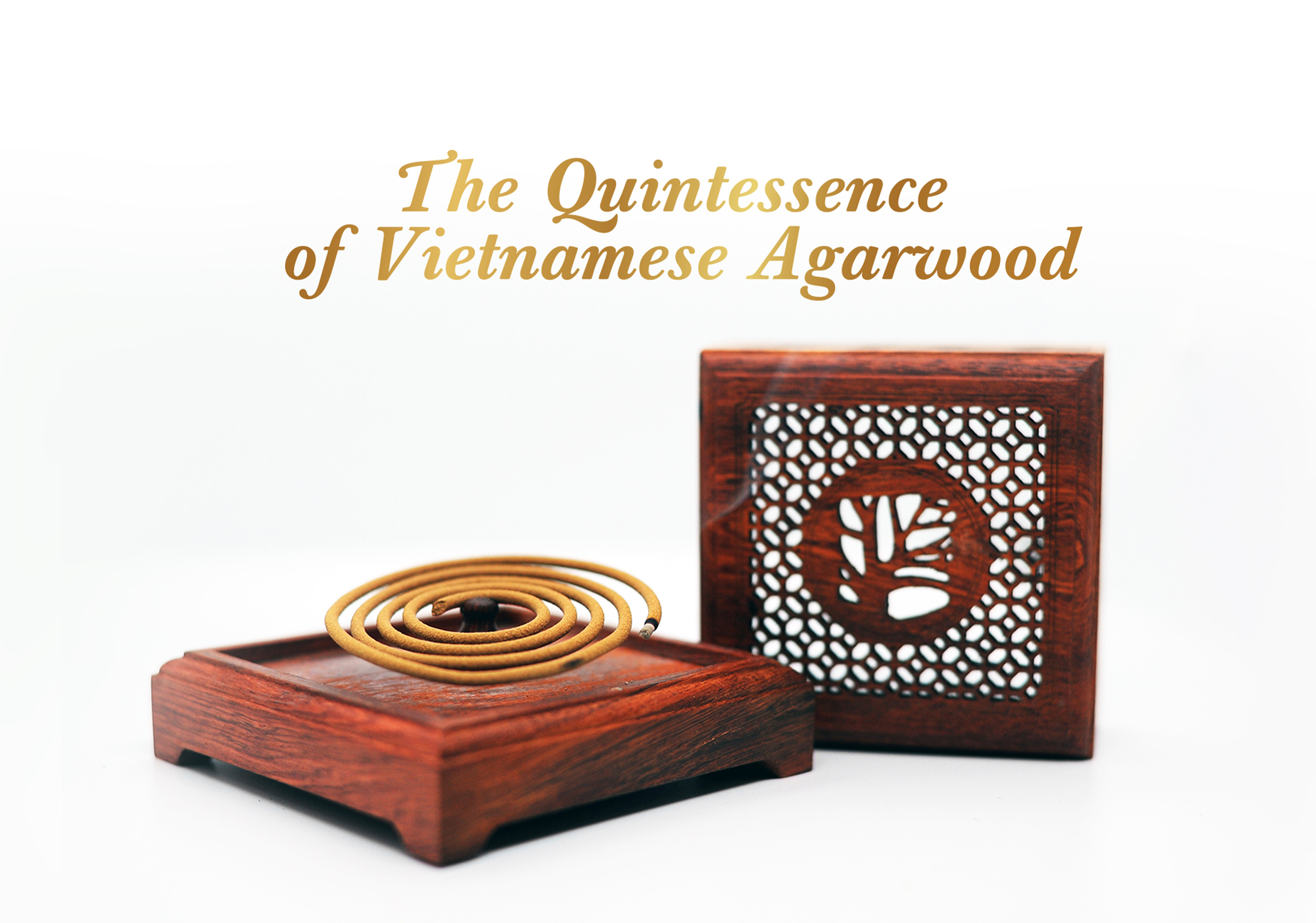

In the past, Vietnam Oud chip lovers used to use wooden goods, which can be mentioned as Oud chips: the long, thin beveled pieces of Oud, collected from the thin outer bark of the Aquilaria Crassna tree; or chunk which is the part of Oud that is formed in the form of a nest, and requires a lot of work to harvest because it has to clean the white wood that does not create Oud in the inner circular cavities.

Oud chip products are the most original type of Oud chips enthusiasm, giving the characteristic warm aroma of Oud chips, usually burned on pre-burned activated carbon. The heat from the smoldering fire emitted from the activated charcoal will cause the Oud chips to burn gently, boiling the oil veins on the wood and releasing the smoke of the incense.

![]()

![]()

Vietnam Oud chips from HAGA Oud: grades & types

Understanding this reaction process, after much research and experiments, Hoang Giang Agarwood manufacturer decided to market the thickness of HAGA Oud Chip in 0.5mm, 0.8mm, 1.0mm.

Accordingly, the 1.0mm thickness type is the thickest of the three types, the white wood remaining on the HAGA Oud Chip piece is the most, giving the longest burning time, the moderate essential oil level for the moderate aroma of Oud. The price of the HAGA Oud Chip 1.0mm type is also cheaper, for general consumption, daily burning in large quantities.

The HAGA Oud Chip 0.5mm thickness type is the thinnest for the most authentic experience of Vietnam Oud chip scent. With this thinness, the amount of white wood remaining is extremely small, so when being used, the original scent of HAGA Oud Chip will emit immediately, extremely passionate and seductive, leaving the fragrance for a long time on the body or furniture.

However, this is also the type with the highest price, and limited output, often chosen to use for special and formal occasions such as festivals, and celebrations,…

The HAGA Oud Chip 0.8mm thickness type has a moderate thickness of the three types, recently developed and released. Realizing market demand, the Hoang Giang Agarwood manufacturer offers an average thickness between 1.0mm and 0.5mm, giving the closest Vietnam Oud chip scent experience to 0.5mm but lower cost, close to 1.0mm and does not detract from any of the relishing quality of Oud Chip.

—

However, this is an expensive way to enjoy Oud chips compared to other products from Oud chips, because the thin pieces of Oud chips will burn very quickly, and need the person enjoying the scent to continuously add Oud chips to maintain the experience.

Not only does it consume a lot of Oud chips in a short time, but the continuous use of activated carbon is also not a safe choice for health, especially for vulnerable subjects such as children and pregnant women and elderly people, people with respiratory diseases, etc.

PROUD TO BE AN AGARWOOD/OUD PRODUCT SUPPLIER OF

Distributors:

UAE distributor:

- Email us at info@uaemarket.ae

- Call us at +971551111194

- DM @hagaoud.gcc

KUWAIT distributor – RIVAL:

- Mubarakiya – Eid Al-Nassar Street – opposite Al Mubarakiya School.

- Call us at +96565690555

- DM @hagaoud.kw

OMAN distributor – TAPPITU OUD:

- Almuwallah South, behind Muscat City Centre, Way no.1748, Building No.3686, Shop No.3686H, Muscat, Oman.

- Call us at +96899244467

- DM @hagaoud.om

Our valued partners

- Arabian Oud

- Ajmal Perfumes

- Afkar General Trading Chain store

- Oudh Al Anfar

- Nabeel Perfumes

- Naseem Perfumes

- Beauty Blends

- Sultan Al Mahruqi Trading retailer

Why choose us – choose Hoang Giang Agarwood’s products

- Factory with modern production line from material to the final product.

- 100% natural Agarwood/Oud ingredient.

- All products are produced in accordance with ISO 9001: 2015 qualification standards, export qualifications, nontoxic chemicals.

- TOP 10 Key Players of Agarwood/Oud essential oil market in the world (Market Research Future 2017).

ISO 9001: 2015 certificated Agarwood (Oud) products, commit to production in accordance of Standard basic announced

On 08.05.2019, Hoang Giang Agarwood Co., Ltd has received an official copy of ISO 9001: 2015 certificate of Directorate for Standards, Metrology and Quality of AQS GLOBAL on product quality management, worldwide recognized for Agarwood (Oud) production and trading.

The ISO 9001: 2015 certificate of Hoang Giang Agarwood is valid for 3 years until April 25, 2022 and is periodically monitored and evaluated to ensure that Hoang Giang’s Agarwood (Oud) product quality always meets the standard certified.

ISO 9001: 2015 certificate assessed by a prestigious international organization is a safe quality assurance for all Agarwood (Oud) products of Hoang Giang, thereby helping customers and partners to feel secure when choosing and believing in Hoang Giang Agarwood (Oud) product in particular as well as Hoang Giang company in general.

LEAVE A REPLY below if you have any interest in making Hoang Giang Ltd. your best supplier. We always offer FREE SAMPLE for our customers.

See our products here

HOANG GIANG AGARWOOD CO., LTD.

Main office & Factory: Nguyen Minh Chau Street, Hiep Cuong Hamlet, Lagi Town, Binh Thuan Province, Vietnam.

Trade office: L40, Street No.11, Him Lam residential area, Tan Hung Ward, District 7, Ho Chi Minh City, Vietnam

Hotline: +84 973 770 639 (available on whatsapp & viber)

Email: info@hgagarwood.com

Website: hgagarwood.com