HAGA Smartoud Production Process – Standards at Every Stage

In the world of fragrances, Smartoud is a high-end product line that not only has spiritual value but is also a symbol of purity and peace. But few people know that, to make a quality Smartoud, it is necessary to go through a rigorous journey from selecting raw materials to testing output quality.

At HAGA Oud, every step in the Smartoud production process is meticulously carried out by hand, combined with modern technology, ensuring the finished product meets international quality standards.

So what does that process include? Let’s explore the entire HAGA Smartoud production process, where the quintessence of heaven and earth is crystallized in each small Smartoud.

1. Selecting input materials – Quality Oud chips are the foundation

The first and most important step in the HAGA Smartoud production process is the selection of raw materials. At HAGA Oud, only natural Oud chips – the wood part containing the most essential oils of the Aquilaria tree – are selected to create Smartoud.

These Oud chips must meet strict standards: rich aroma, characteristic dark brown color and absolutely no impurities. The quality of raw materials is the decisive factor in the aroma and burning ability of Smartoud after completion.

HAGA does not use mixed wood, does not mix white wood or chemicals in any production stage – this is an important commitment that creates the difference of the brand.

2. Grind into powder – 100% pure Oud powder, no chemicals

After selecting the best Oud chips, the raw materials will be ground to create pure Oud powder.

Notably, this process only uses clean water to bind – absolutely no industrial glue, scented chemicals or synthetic additives are used. This helps ensure that Smartoud products are not harmful to the health of users, while preserving the rustic, pure aroma typical of natural Oud.

For HAGA Oud, the value of Oud lies in its purity, and that starts with the quintessential powder ground from natural Oud chips.

3. Shaped & naturally dried – Ensures burning and aesthetics

Next, the Oud powder is put into the bud shaping stage. At HAGA, this stage is mostly done by hand or with a specialized mold to create a uniform and beautiful shape.

After shaping, Smartoud will be naturally dried in the sun, instead of being dried by machine, to preserve the pure aroma and help Oud burn stably, without burning or crumbling when burned.

This process is closely monitored by the quality control (QC) team. Each batch of Oud after drying is checked for hardness, color, even burning ability and natural aroma, ensuring that only the best Smartoud is packaged.

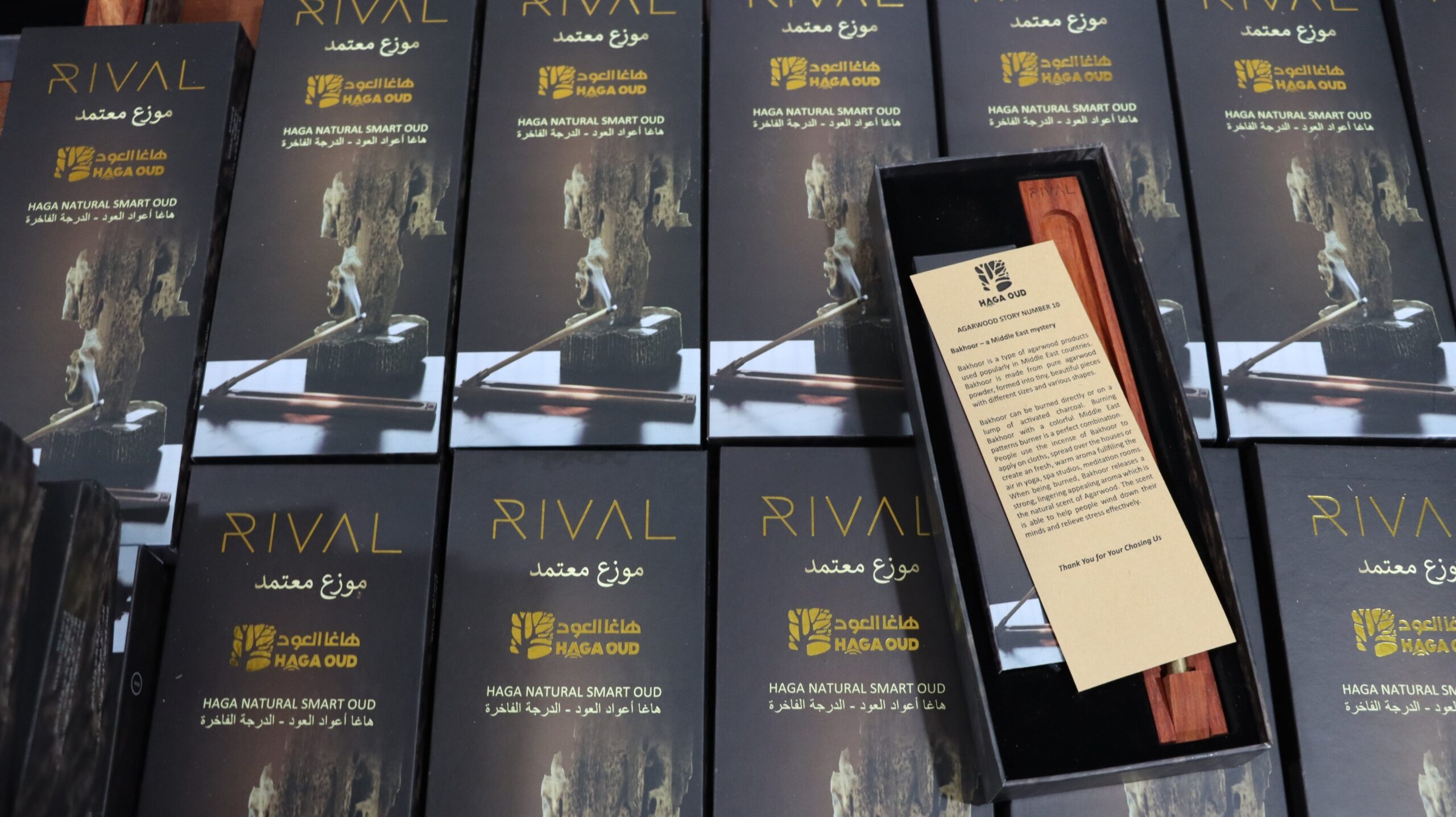

4. Product packaging & finishing – Meets TCCS standards & ISO 9001:2015 certification

After going through the processing and inspection stages, HAGA Smartoud will be professionally packaged according to each product type. Each Oud box shows the investment from packaging design to printing, demonstrating the class and meticulousness of the brand.

In particular, HAGA Oud’s Smartoud products have met TCCS (Basic Standards) standards and ISO 9001:2015 certification – an international standard for quality management, showing that the production process at HAGA is not only clean, standard, and safe but also systematic and sustainable.

Why do customers trust HAGA Smartoud?

- 100% natural Oud ingredients – no chemicals, no synthetic fragrances.

- The scent is natural, pure, and gentle, and it feels relaxed and pure.

- Burning evenly, with no burning smell, is suitable for meditation, chanting, worshiping, or daily relaxation.

- The production process meets standards, ensuring safety for users’ health and being environmentally friendly.

HAGA Oud – The quintessence of Vietnamese Oud in each small piece

HAGA Oud is not only a brand, but also a journey to preserve and develop the traditional values of Vietnamese Oud. By investing in a methodical, transparent and safe production process, HAGA Oud brings Smartouds that are not only of high quality but also carry the spirit, spirituality, and cultural identity of Vietnam.

Choose HAGA Smartoud, where each Smartoud is a masterpiece of dedication, sophistication, and respect for nature.

Hoang Giang Agarwood Ltd, Co is the leading Oud manufacturer in Vietnam, especially famous for the HAGA Oud brand: (1) Committed to delivering Oud products with good and consistently stable quality amongst all batches; (2) Reasonable, competitive prices and transparent, clear pricing policies.

Learn more about our Oud products at https://hgagarwood.com/products-page

The GCC region has official distributors, specifically in the UAE, Kuwait, Oman, and Saudi Arabia.

Firstly, UAE distributor – AHAYCO GROUP:

- Email us at info@uaemarket.ae

- Call us at +971551111194

- DM @hagaoud.gcc

Secondly, KUWAIT distributor – RIVAL:

- Mubarakiya – Eid Al-Nassar Street – opposite Al Mubarakiya School.

- Call us at +96565690555

- DM @hagaoud.kw

In addition, the OMAN distributor – ECCESSWARY:

- Address: 23 July Street, Salalah City. Our branches in Muscat-Salalah-Sohar-Sur.

- Call us now at +968 9123 9588

- DM @hagaoud.om

Moreover, the SAUDI ARABIA distributor: DM @hagaoud.ksa

Moving on, QATAR distributor – RIVAL: DM @hagaoud.qa

Furthermore, our valued partners:

- The first is Arabian Oud

- The next is Ajmal Perfumes

- Followed by the Afkar General Trading Chain store

- Then is Oudh Al Anfar

- After that, Nabeel Perfumes

- Subsequently Naseem Perfumes

- In addition, Beauty Blends

- And finally Sultan Al Mahruqi Trading retailer

Finally, why choose us – choose Hoang Giang Agarwood’s products

- Firstly, the factory with modern equipment makes products from start to finish.

- Secondly, we use 100% natural Agarwood/Oud.

- Thirdly, All products follow ISO 9001:2015 standards and export rules. And nontoxic chemicals.

- Finally, we are in the top 10 Agarwood/Oud essential oil companies worldwide (Market Research Future 2017).