Questions for how HAGA Oud grows our Aquilaria Crassna plantation

After publishing the “Agarwood (Oud) documentary: a film by Hoang Giang Agarwood manufacturer” on the HAGA Oud YouTube channel, the industry received much attention and pointed questions.

Questions about HAGA Oud’s Aquilaria Crassna plantation

A viewer, as a professional perfumer and avid consumer of Oud oils, commented below the video that “could not you just scrub the infected, transformed agarwood (normally ‘It’ (the resin-rich dark bits and blobs) is anyway painstakingly scrubbed out from the healthy wood)-instead of cutting whole such young trees-re-infect them, to create a new exterior layer of biotreatment, letting tree continue to grow and keep producing the Oud?”

He also noticed “how little fungal rot you have on the wood logs, only on the surface, with no resin-rich core. Minding, that the real ‘Kynam’-in its precise definition, is that accumulated resin, the immune response excreted liquid, not the fungi rot itself, and that’s why true high-grade Kynam oils have rather translucent beautiful color (not opaque dark brown) like orange or purplish red, or even pure green.”

The viewer supposed that the “productive age of the trees for Oud is 15-40 years, with best samples older, after a much longer maturation period, I have honest doubts, that a Kynam-quality superior (as you claim) oil can be produced with your current method, from such young trees, after such a short ripening time.”

To answer those interesting questions about how HAGA Oud grows our own Aquilaria Crassna plantation for raw material of Agarwood (Oud) products, we listed below the information which hopes to solve doubts about HAGA Oud’s Aquilaria Crassna plantation.

Does HAGA Oud use kynam as our raw material?

Aquilaria Crassna tree grows best under the conditions of some tropical rain forests in Southeast Asia, including Vietnam, suitable with red basalt soil or gravel soil. When the tree is diseased or affected by nature, its resin overflows to cover the wound, creating an oily and fragrant piece of wood. Depending on the amount of resin formed that people in the profession call by different names: tok, Agarwood (Oud), kynam.

- Tok: due to a partial transformation of wood, forming dark lines like hair (low amount of essential oils, often used as making incense)

- Agarwood (Oud): this is due to the incomplete differentiation of the wood particles, absorbing Agarwood (Oud) oil more than tok, brown, or black stripes. The better the Agarwood (Oud) type, the less floating in the water.

- Kynam: is the best type, due to the complete transformation of wood particles, absorbing a lot of Agarwood (Oud) essential oil, dark brown, black, green, yellow, or white. Kynam is heavy, submerged in water, has a bitter taste, often formed in the core of the Agarwood (Oud) tree.

The first thing to clarify is the point that we do not use kynam as our raw material for all of HAGA Oud products since they are forbidden from harvesting in Vietnam as well as hardly exist on earth. Our material is Agarwood (Oud) (same type but slightly softer and more abundant), which is the kind of wood that is licensed for harvest and cultivation.

Of the three types of forests classified under Vietnamese law, the forest used to supply the raw material source for HAGA Oud products is the Production Forest used to produce timber and other forest products. Exploiting forest products in the production forest needs to meet the conditions after clearing the forest to re-plant the forest right in the next planting season or regenerate the forest.

HAGA Oud raw material source-Agarwood (Oud) used for trading and creating value-added products from Hoang Giang Agarwood manufacturer is supplied from two sources: from Aquilaria Crassna tree plantation of HAGA Oud and from other farmer households that we cooperate with, guide, technology transfer, and off-take.

Why doesn’t HAGA Oud just use the resin part and then let the tree continue its life?

We don’t just cut the resin part then re-infect them, cause we use the whole mature infected cultivated tree which is aged 12-13 years, including Agarwood (Oud) chip (thin part), Agarwood (Oud) chunk (trunk core) the white wood part which is less resin than others.

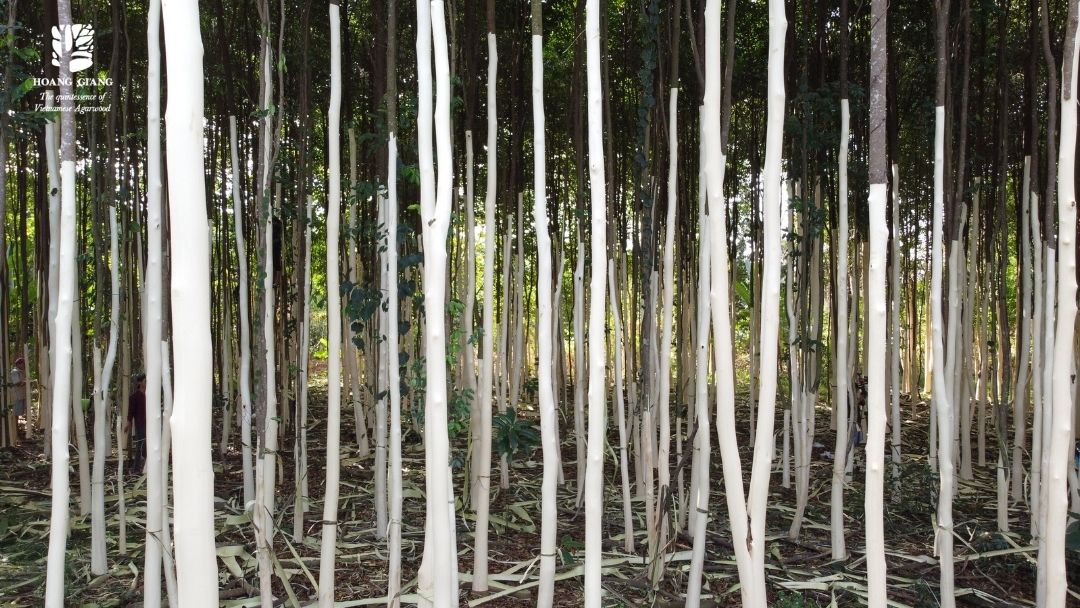

Agarwood (Oud) chips are cultivated from Aquilaria Crassna trees planted in Hoang Giang Agarwood manufacturer’s plantation, totally free of toxic chemicals or artificial color. Two sides of the HAGA Agarwood Chip are mainly resin with very little white wood left.

HAGA Agarwood Chip is peeled off from the injured bark inside Vietnamese Aquilaria Crassna trees, then treated by skilled artisans. After many hours of carefulness, they turn a rough log into a very thin flat chip totally by hand. The majority of the 2 sides is resin, with little white wood left. Thus, when burning this Agarwood (Oud) on charcoal, you will feel a very sweet and warm aroma without the bitter smoke of ordinary wood.

HAGA Agarwood Chunk is collected from the highly resinous inside parts of Aquilaria Crassna trees grown on our plantation in Binh Thuan province. Totally crafted by hand, the HAGA Agarwood chunk is the best quality, naturally hollow inside. The black, light brown HAGA Agarwood chunk scent is pleasant, soft sweet woody.

At which age is the Aquilria tree sufficient for harvest?

Aquilaria Crassna growers wait for the tree to reach its mature age at 8-10 then use various methods to stimulate the tree to secrete its own resin. After 2-3 years, that layer of resin solidifies will form Agarwood for harvesting.

Agarwood (Oud) has been collected after 2 or 3 years from the implantation. No fragrance is added to strengthen the scent of the wood, so the smell is natural and soft at room temperature.

From a stable input source of the area of 50ha Aquilaria Crassna plantation, Hoang Giang Agarwood manufacturer could operate smoothly with substantial capacity every month. Thereby, our HAGA Oud product could be always available for a stable capacity with a reasonable price, resulting from our total control from the input material source to the closed production process to final products and considerable experience in exporting worldwide by over 07 years of international trade.

Why choose us – choose HAGA Oud’s products

- Factory with modern production line from material to final product.

- 100% natural Agarwood/Oud ingredient.

- All products produced by ISO 9001: 2015 qualification standards, export qualification, and nontoxic chemicals.

- TOP 10 Key Players of the Agarwood/Oud essential oil market in the world (Market Research Future 2017).

ISO 9001: 2015 certificated Agarwood (Oud) products commit to production in accordance of Standard basic announced

On 08.05.2019, Hoang Giang Agarwood Co., Ltd has received an official copy of ISO 9001: 2015 certificate of Directorate for Standards, Metrology and Quality of AQS GLOBAL on product quality management, worldwide recognized for Agarwood (Oud) production and trading.

The ISO 9001: 2015 certificate of Hoang Giang Agarwood is valid for 3 years until April 25, 2022 and is periodically monitored and evaluated to ensure that Hoang Giang’s Agarwood (Oud) product quality always meets the standard certified.

ISO 9001: 2015 certificate assessed by a prestigious international organization is a safe quality assurance for all Agarwood (Oud) products of Hoang Giang, thereby helping customers and partners to feel secure when choosing and believing in Hoang Giang Agarwood (Oud) product in particular as well as Hoang Giang company in general.

LEAVE A REPLY below if you have any interest in making Hoang Giang Ltd. your best supplier. We always offer FREE SAMPLE for our customers.

See our products here

HOANG GIANG AGARWOOD CO., LTD.

Main office & Factory: Nguyen Minh Chau Street, Hiep Cuong Hamlet, Lagi Town, Binh Thuan Province, Vietnam.

Trade office: 62, Street No.7, Him Lam residential area, Tan Hung Ward, District 7, Ho Chi Minh City, Vietnam

Hotline: +84 973 770 639 (available on WhatsApp)

Email: info@hgagarwood.com

Website: hgagarwood.com