How HAGA Natural Agarwood Oil is made? (Part 2)

Essential oils are the most important and valuable product line extracted from Agarwood (Oud). That is why Hoang Giang Agarwood company has devoted a lot of effort and enthusiasm to maximize both the output and quality of HAGA Natural Agarwood Oil from the world’s best Aquilaria crassna.

4. Agarwood oil from Agarwood (Oud) formed in nature and by humans

The mechanism of creating Agarwood (Oud) in nature and in the bussiness of purchasing and production of Agarwood (Oud) is completely the same.

In nature, the trees that are capable of forming Agarwood (Oud) often begin to accumulate the myrrh layer when the trunk is wounded for reasons such as ants, bees nesting, or being struck by thunder, booms in wars, etc,…

When injured, the trunk secretes a layer of myrrh as a mechanism of wound healing. Over time, the myrrh layer hardens, is covered by the bark and forms Agarwood (Oud) inside the trunk.

5. Misconceptions about the definition of “industrial Agarwood (Oud) or Agarwood oil”

Based on that mechanism, people now know how to stimulate the trunk of Agarwood (Oud) tree, often called the “take impact on the tree” stage by implanting ants or other insects to make nests on the trunk, or some other microorganisms, etc. to stimulate the plant to form Agarwood (Oud) for harvest.

As such, this explanation rejects the misconceptions about the definition of “industrial Agarwood (Oud)” being misunderstood in the market because of the whole process of forming Agarwood (Oud) and the process of producing products form Agarwood (Oud) is completely natural and made by human’s hands as a folk craftsmanship.

6. Method of extracting HAGA Natural Agarwood Oil of HAGA Oud

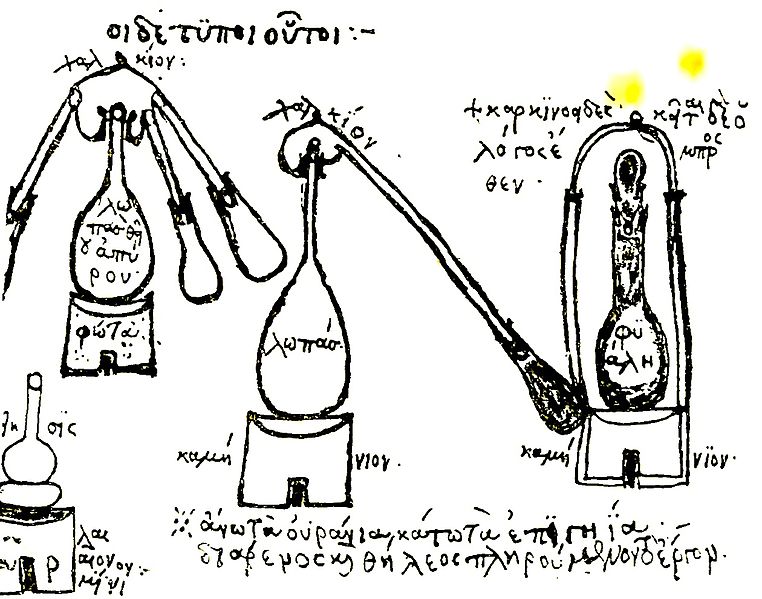

The method used by HAGA Oud to produce the product line of HAGA Natural Agarwood Oil is steam distillation, one of the methods that has appeared since ancient times and is considered the most effective in terms of producing the best oil quality and minimizing the losses in quantity.

With this method, Agarwood (Oud) is ground into powder, soaked in water to create a wet powder mixture and distilled. Steam – the result of distillation – where aromatic plant molecules are captured and condensed.

Pure Agarwood (Oud) essential oil will usually float on hydrosol (distilled water component) and can be collected separately from other ingredients. As the condenser cools, the pure oil and hydrosol are separated, the oil is used as the essential oil.

This method protects essential oils extracted to a certain degree, since the amount of water surrounding the essential oil acts as a barrier to prevent the oil from becoming too hot.

Steam distillation can be performed at reduced pressure (in a vacuum) to lower the temperatures to below 100 ° C, which is very useful in protecting plant materials as well as essential oils.

7. Advantages of steam distillation method for Agarwood (Oud) oil

Although steam distillation is the most common method for extracting and isolating essential oils because in perfume, high temperatures can destroy the smallest aroma molecules, so steam distillation is often preferred, but it is a time consuming process and requires a large amount of plant material.

This extraction and filtration process uses purified steam to remove all impurities. As a result, Hoang Giang’s HAGA Natural Agarwood Oil is guaranteed to be 100% pure and free of chemicals.

Why choose us – choose Hoang Giang Agarwood’s products

- Factory with modern production line from material to final product.

- 100% natural Agarwood/Oud ingredient.

- All products produced in accordance with ISO 9001: 2015 qualification standards, export qualification, non toxic chemicals.

- TOP 10 Key Players of Agarwood/Oud essential oil market in the world (Market Research Future 2017).

ISO 9001: 2015 certificated Agarwood (Oud) products, commit to production in accordance of Standard basic announced

On 08.05.2019, Hoang Giang Agarwood Co., Ltd has received an official copy of ISO 9001: 2015 certificate of Directorate for Standards, Metrology and Quality of AQS GLOBAL on product quality management, worldwide recognized for Agarwood (Oud) production and trading.

The ISO 9001: 2015 certificate of Hoang Giang Agarwood is valid for 3 years until April 25, 2022 and is periodically monitored and evaluated to ensure that Hoang Giang’s Agarwood (Oud) product quality always meets the standard certified.

ISO 9001: 2015 certificate assessed by a prestigious international organization is a safe quality assurance for all Agarwood (Oud) products of Hoang Giang, thereby helping customers and partners to feel secure when choosing and believing in Hoang Giang Agarwood (Oud) product in particular as well as Hoang Giang company in general.

LEAVE A REPLY below if you have any interest in making Hoang Giang Ltd. your best supplier. We always offer FREE SAMPLE for our customers.

See our products here

HOANG GIANG AGARWOOD CO., LTD.

Main office & Factory: Nguyen Minh Chau Street, Hiep Cuong Hamlet, Lagi Town, Binh Thuan Province, Vietnam.

Trade office: 62, Street No.7, Him Lam residential area, Tan Hung Ward, District 7, Ho Chi Minh City, Vietnam

Hotline: +84 973 770 639 (available on whatsapp)

Email: info@hgagarwood.com

Website: hgagarwood.com